Menu

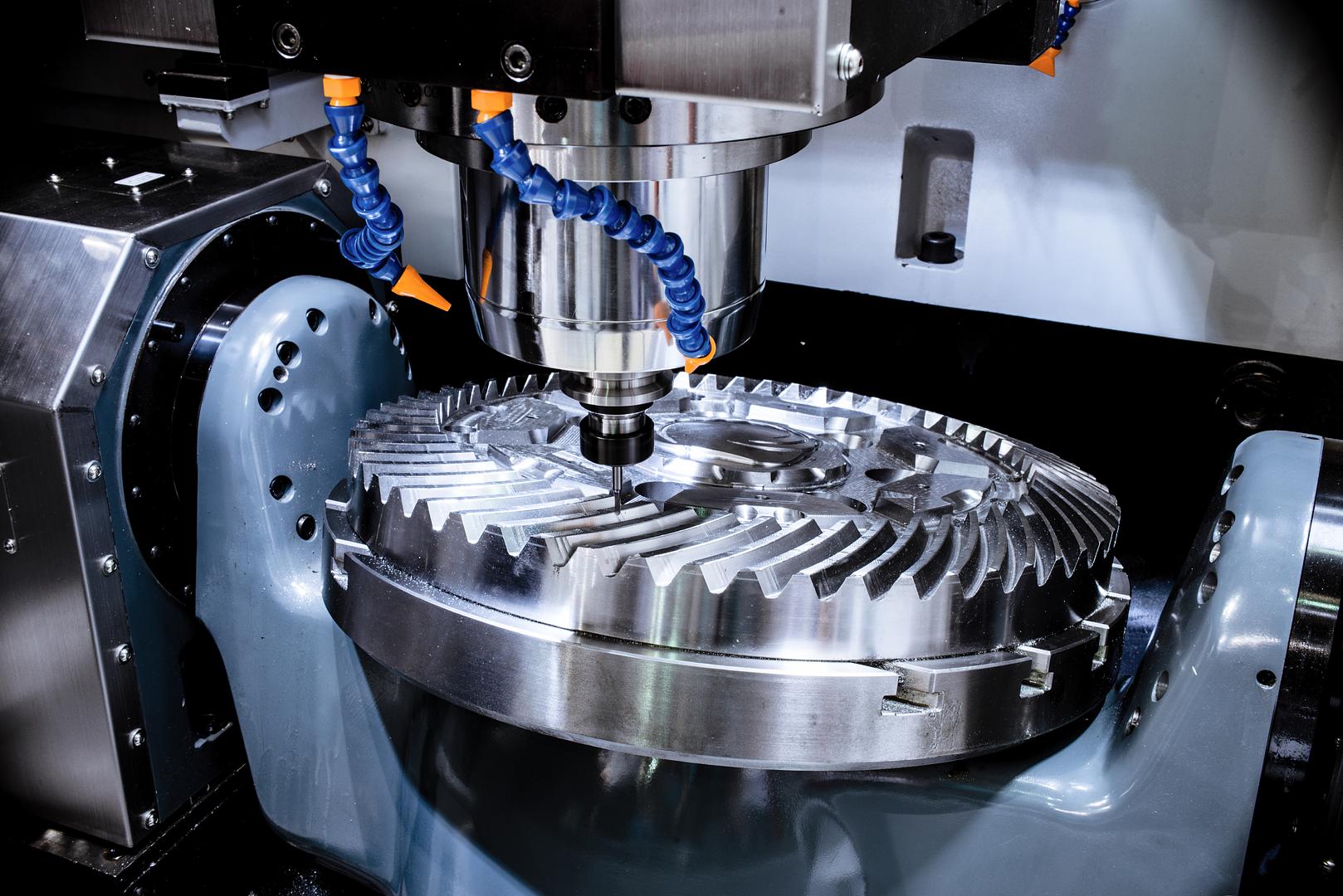

Buying a used CNC machine can be a smart way to expand your workshop without the high costs of new equipment. But choosing the wrong machine can lead to expensive repairs and downtime. Here’s how to make the right decision.

Why Buy Used CNC Machines?

Lower costs – Save 30–70% compared to new models.

Faster ROI – Depreciation has already occurred, meaning quicker payback.

Proven reliability – Many models have strong track records.

Immediate availability – No waiting months for delivery.

Key Things to Check

Age & Usage Hours – Low hours can matter more than age.

Service History – Look for regular maintenance and repairs.

Control System – Make sure the CNC control (Fanuc, Siemens, Heidenhain, etc.) is still supported.

Mechanical Wear – Check beds, slides, and ball screws for accuracy.

Test Runs – Always ask for a demo cut or inspection report.

Why Professional Valuation Matters

Knowing the real market value protects you from overpaying or underselling. At GD Machinery, our Instant Valuations give you a quick, accurate estimate backed by decades of industry experience.

Buy with Confidence

Since 1995, GD Machinery has supplied quality CNC lathes, machining centres, borers, grinders, and presses to businesses worldwide. With full inspections, sourcing support, and turnkey services, we make buying used machinery safe and simple.